Description

| After-sales Service: | Within The Warranty to Provide Free Accessories |

|---|---|

| Warranty: | 15 Months After Leaving The Factory |

| Type: | Marine Cooling Equipment Specific Air Conditioner |

| Air Tube Material: | Galvanized Sheet |

| Corrosion Durability: | Non-Standard Custom |

| Operating Voltage: | 380/400 VAC |

|

Customization: |

Available

|

|---|

Basic Info.

|

Model NO.

|

HS-WG10Q

|

|

Application Fields

|

The Ship

|

|

Lifetime

|

>20 years

|

|

Condition

|

New

|

|

Refrigerant

|

R22, R404A, R407c, R134r

|

|

Compressor Types

|

Piston Compressor

|

|

The Condenser

|

High Efficiency Tube and Shell Heat Exchanger

|

|

Transport Package

|

Fully Enclosed Export Packing

|

|

Noise Level

|

Ordinary

|

|

Mounting

|

Floor Standing

|

|

Certification

|

CCC

|

|

Compressor Brand

|

Copeland/Dai.Kin/Panasonic/Hitachi

|

|

Refrigerating Capacity

|

7kw-86kw

|

|

Fan

|

Low Noise Centrifugal Fan

|

|

Machine Custom

|

According to The Demand for Custom-Made

|

|

Specification

|

Non-Standard Custom

|

Marine air conditioner is widly used in

*Marine

*offshore

*ship

*container ship

*vessel

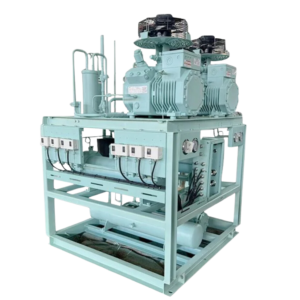

Photos

| Water-cooled Marine Air Conditioner — top air supply (R407C) | ||||||||

| Parameter Model | HS-WG10Q | HS-WG17Q | HS-WG27Q | HS-WG35Q | HS-WG42Q | HS-WG50Q | ||

| Refrigeranting capacity | KW | 8.5/11.0 | 14.0/17.0 | 20.0/24.0 | 24.0/30.0 | 18.0*2/21.0*2 | 20.0*2/24.0*2 | |

| Electric heating | KW | 8 | 14 | 22 | 28 | 34 | 40 | |

| Power supply | 3P-440-50HZ/60HZ | |||||||

| Refrigerant | type | R407C | ||||||

| Compressor | type | piston Compressor | ||||||

| qty | set | 1 | 1 | 1 | 1 | 2 | 2 | |

| power | kW | 2.9/3.6 | 4.3/5.2 | 6.3/7.6 | 7.2/8.8 | 5.8*2/6.8*2 | 6.3*2/7.6*2 | |

| Condenser | type | |||||||

| water volume | m3/h | 3.2/3.9 | 5.1/6.1 | 7.2/8.6 | 8.8/10.7 | 12.8/15.2 | 14.4/17.2 | |

| connection pipe size | DN | 25 | 32 | 50 | 50 | 65 | 65 | |

| water resistance | Kpa | 50 | ||||||

| Evaporator | type | Copper tube string sleeve type | ||||||

| fin form | Corrugated copper fins/Corrugated hydrophilic film aluminum fins | |||||||

| Throttling method | External balanced thermostatic expansion value | |||||||

| Fan | type | Low noise centrifugal Fan | ||||||

| driving mode | belt driven | |||||||

| power | KW | 0.55/0.86 | 0.55/0.86 | 1.1/1.27 | 1.1/1.27 | 2.2/2.53 | 2.2/2.53 | |

| air volume | m3/h | 1000/1200 | 15000/1800 | 2100/2500 | 2600/3000 | 23800/4400 | 4200/4900 | |

| external static pressure | Pa | 400 | ||||||

| Safety protection device | high / low pressure protection, current overload protection, water flow protection, Electronic time delay protection etc | |||||||

| Unit drain pipe | DN | 25 | ||||||

| Outline dimension | W(mm) | mm | 800 | 1050 | 1200 | 1450 | 1700 | 1900 |

| D(mm) | mm | 550 | 580 | 700 | 700 | 800 | 900 | |

| H(mm) | mm | 1610 | 1610 | 1700 | 1700 | 1800 | 1800 | |

| Unit weight | kg | 265 | 300 | 460 | 540 | 600 | 680 | |

Compressor

The compressor is the core of the refrigeration system. Compared with land-based air conditioners, the compressors of marine air conditioners operate in inclined swings, and the fuel supply problem is more prominent. Poor oil supply will cause serious damage to the compressor. The deep oil tank design ensures the oil supply of the compressor on the ship in a tilting and swaying environment. The anticorrosion of the compressor is sprayed with naval special anticorrosive paint after the outer surface is sandblasted.

Condenser

The condensers for marine air conditioners are divided into seawater water-cooled and air-cooled condensers. The seawater condenser is directly cooled by seawater. It is necessary to prevent the highly corrosive seawater corrosion and the smoothness of the refrigerant supply liquid when the hull is swaying. The air-cooled condenser needs to be protected from salt spray corrosion. The water-cooled condenser uses Bfe10-1-1 heat transfer tube with strong anti-corrosion ability, the end cover is made of cast aluminum bronze, and the tube sheet is made of (HA177-

2 / 16MnR) composite materials, and additional safety valves are added to ensure safety, and anti-potential corrosion equipment is added to the seawater side. For the liquid supply problem of the water-cooled condenser, add a liquid storage bag to the lower part of the condenser. The air-cooled condenser uses a copper sheet-covered copper tube heat exchanger to improve the resistance to salt spray.

·Evaporator

Marine evaporators are also divided into water-cooled and air-cooled. Corrosion protection still needs to be considered. The water-cooled evaporator uses a dry shell-and-tube evaporator, which is the same as the land-based evaporator, but still needs to consider the anti-corrosion measures on the outer surface of the evaporator, and add a plated steel shell on the outer surface to enhance the corrosion resistance of the evaporator. The air-cooled finned evaporator uses a high-efficiency copper tube jacketed type.

Throttling mechanism

In addition to throttling, the expansion mechanism also plays a role in regulating the flow of refrigerant into the evaporator. At present, externally balanced thermal expansion valves are commonly used in marine air conditioners.

System accessories

The main components of the refrigeration system are dry filters, oil storage tanks, gas-liquid separators, solenoid valves, sight glasses, pressure gauges, shock absorbers, high and low pressure protectors, etc., which are used to better detect the operation of the system and protect the operation of the system. Safety and reliability. Among them, the installation of marine air-conditioning accessories, such as sight glass, should be threaded to avoid welding. The marine air conditioner solenoid valve needs to be equipped with a manual control lever.

Selection of fan and motor

Marine fans and motors still need to consider anti-corrosion and anti-tilt factors. The impeller of the marine air conditioner fan requires strict dynamic balance correction and overspeed test. The material of the impeller is made of anti-corrosion aluminum alloy. The whole casing is welded to meet the requirements of ship strength, impact resistance and corrosion resistance. The selection of marine motors except when the ship periodically tilts up to 45 °. It is required that the motor can work reliably and can still work without damage when the long-term horizontal and vertical tilt reaches 15 °, and a filter must be installed to prevent electromagnetic interference.

Marine duct design

The main features of the circulating air piping system are small space, high heat generation, and very limited layout space on board. When designing the air duct, it is necessary to fully consider the vibration isolation, vibration reduction and noise reduction of the air duct, minimize the resistance loss, adjust the air volume and the actual space layout of the ship. A return air box should be provided at the air inlet and outlet respectively. In order to reduce the vibration transmission during the operation of the special air conditioner, a small piece of soft connection is connected between the rigid air pipe and the air inlet and outlet interface of the air conditioning equipment.

Design of cooling seawater pipeline

The ship’s cooling water uses highly corrosive seawater, and the sea cement sand content is relatively high. Generally, the cooling seawater flow is designed according to the temperature difference of 4 ºC. The water flow rate in the tube is designed according to 1 ~ 1.5m / s, and the fluctuation range of the cooling seawater temperature is -2 ~ 32 ºC.An electric three-way regulating valve is installed between the inlet and outlet of the cooling seawater. In order to reduce vibration transmission and facilitate docking, a hose connection should be used between the pipeline and the air conditioning interface

Design of cooling seawater pipeline

The frame and leaking parts must be painted and anticorrosive, and the electrical components must be anticorrosive materials and electromagnetic interference.

Reviews

There are no reviews yet.